New Energy Monitoring System Reveals Key Savings

At ETL Systems, we are committed to reducing energy consumption and mitigating our environmental impact across our operations. In January 2024, we took a major step forward by installing a Visible Energy Monitoring System. This state-of-the-art system enables us to monitor our overall electricity consumption and break down the energy use of key equipment, including air conditioning and plant facilities.

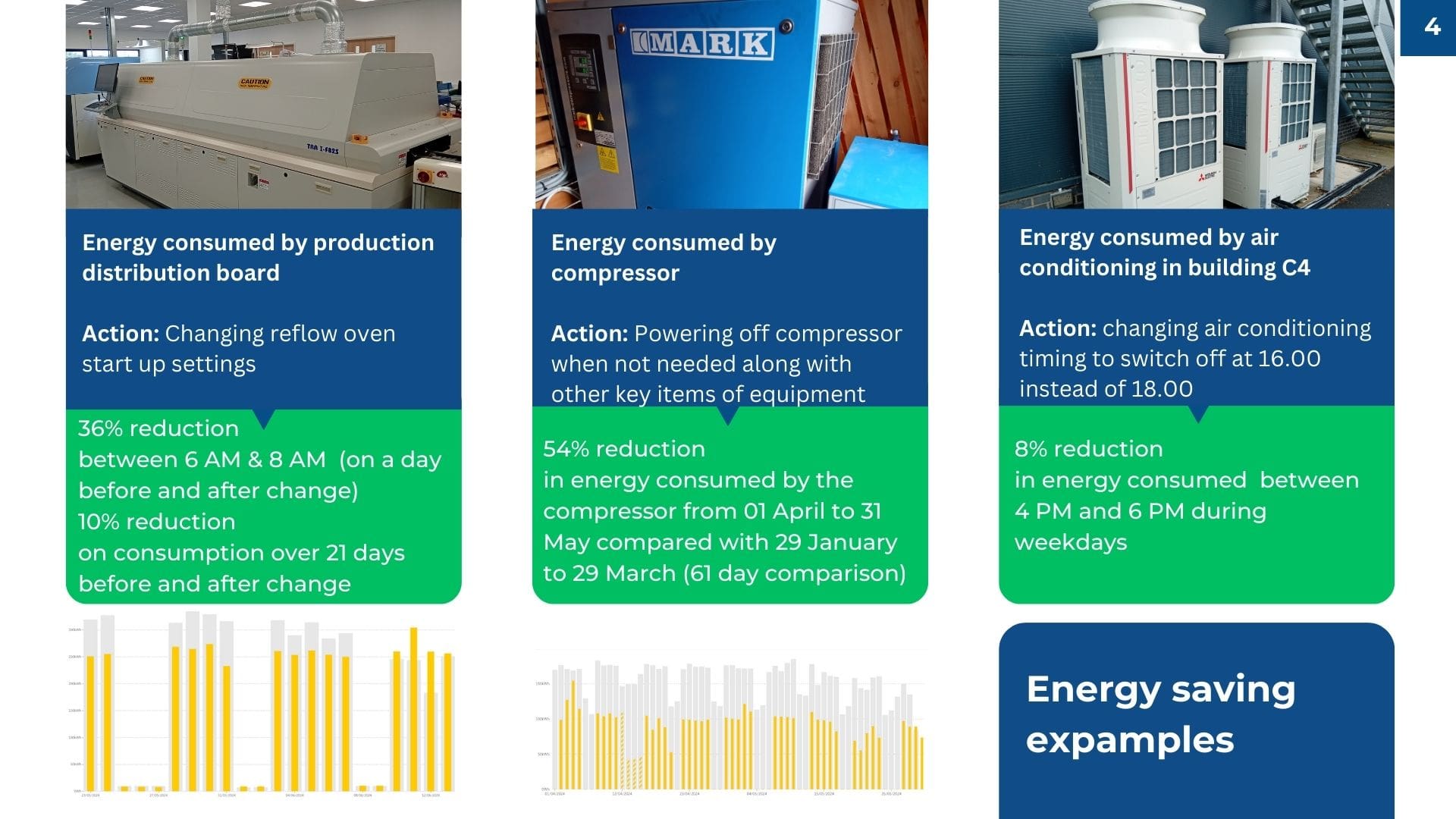

By accurately tracking when and where energy is consumed, we can now identify areas for improvement in savings and take targeted action. Below are three case studies that highlight the immediate benefits we’ve seen since implementing the system.

Case Study 1: Production Distribution Board

Action: Adjusting reflow oven start-up settings.

Results: A 36% reduction in energy usage between 6 am and 8 am when comparing the day before and after the changes. Over a 21-day period, we saw a 10% decrease in overall energy consumption.

Case Study 2: Production Compressor

Action: Powering off the compressor, along with other key equipment, when not in use.

Results: This adjustment resulted in a 54% reduction in energy consumption for the compressor over a 61-day period (from 1 April to 31 May compared with 29 January to 29 March).

Case Study 3: Production Air Conditioning

Action: Changing air conditioning settings to switch off at 4 pm instead of 6 pm.

Results: An 8% reduction in C4 building energy usage between 4 pm and 6 pm on weekdays.

Encouraging Employee Participation

The energy monitoring system doesn’t just help us optimise processes; it also empowers our staff to contribute to energy-saving efforts. We are encouraging team members to share suggestions for small equipment adjustments or process changes. Every idea, no matter how minor, can make a difference—and thanks to our new system, we can track the impact.

Employee involvement is crucial as we continue to work together towards smarter, more efficient energy usage at ETL Systems.

“When team members suggest ways to conserve energy, having access to the energy monitoring system to visualize the impact of these ideas and share the results is incredibly motivating. We have seen that simple measures such as turning things off can significantly reduce energy consumption. As we continue to improve process efficiency and ensure equipment is operating at optimum settings (and turned off when not in use!), we will continue to save energy.

It is also important to highlight our investment in renewable energy. Approximately 40% of our energy consumed at our Hereford site over the summer months is generated from the solar PV on site. Reducing energy consumption and drawing a significant amount of energy from Solar PV are major steps on our carbon reduction roadmap.” Rebecca Lyons – Corporate Compliance Manager

Find out more about this and our other energy initiatives in our latest Energy Saving Report.